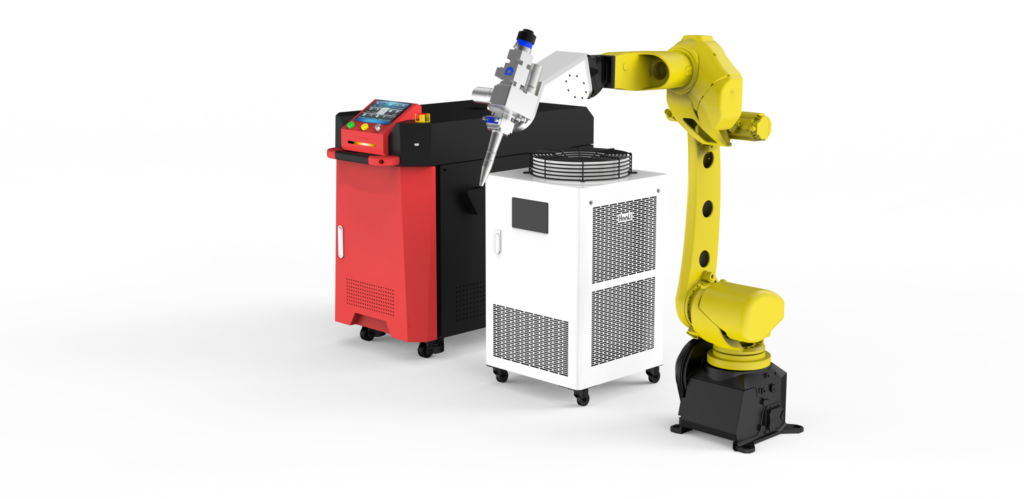

In today’s fast-paced industrial landscape, the demand for precision and speed has never been higher. As manufacturers strive to meet these demands, one technological marvel has emerged as a game-changer: robotic laser welding machine. These advanced systems are revolutionizing the way we think about welding, blending razor-sharp accuracy with unparalleled efficiency. Let’s take a closer look at how these machines are pushing the boundaries of what’s possible.

The Evolution of Welding Technology

Traditional welding methods have served industries well, but they come with inherent limitations. Manual welding, for example, is labor-intensive and prone to human error, while conventional automated welding systems struggle to achieve the same level of precision. Enter robotic laser welding machines, which combine the best of both worlds: the dexterity of a human welder and the consistency of an automated system.

Precision at Its Finest

One of the standout features of robotic laser welding machines is their remarkable precision. Leveraging the power of laser technology, these machines can create welds with micrometer-level accuracy. This is particularly beneficial in industries such as aerospace and electronics, where even the smallest imperfection can lead to catastrophic failures.

The laser beam, guided by a robotic arm, can be fine-tuned to the exact specifications required for the task at hand. This level of control ensures that each weld is as precise as the last, significantly reducing the risk of defects and rework. Additionally, the non-contact nature of laser welding minimizes heat distortion, preserving the integrity of the materials being joined.

Speeding Up Production

Speed is another area where robotic laser welding machines excel. Traditional welding processes can be time-consuming, especially when dealing with complex assemblies or high-volume production runs. Robotic laser welding machines, on the other hand, operate at lightning speed, seamlessly transitioning from one weld to the next with minimal downtime.

This heightened efficiency translates to increased throughput and faster turnaround times, giving manufacturers a competitive edge in the market. Furthermore, the ability to program these machines for continuous operation means they can work around the clock, further boosting productivity.

Versatility in Application

Robotic laser welding machines are not confined to a single industry or application. Their versatility allows them to be used across a wide range of sectors, from automotive manufacturing to medical device production. Whether it’s welding thin sheet metal or intricate components, these machines can handle it all with ease.

Moreover, advancements in software and control systems have made it easier than ever to program and operate robotic laser welding machines. User-friendly interfaces and intuitive programming tools ensure that even those with limited technical expertise can harness the full potential of these systems.

Enhancing Safety Standards

Safety is a paramount concern in any manufacturing environment, and robotic laser welding machines are designed with this in mind. By automating the welding process, these machines reduce the need for human operators to work in close proximity to hazardous equipment and materials. This not only minimizes the risk of injury but also allows skilled workers to focus on more strategic tasks.

Additionally, modern robotic laser welding systems are equipped with advanced safety features, such as collision detection and automatic shutoff mechanisms, further enhancing workplace safety.

The Future of Welding

As technology continues to evolve, so too will the capabilities of robotic laser welding machines. Ongoing research and development efforts are focused on integrating artificial intelligence and machine learning algorithms, which promise to take precision and efficiency to new heights. These advancements will enable machines to adapt to changing conditions in real-time, optimizing weld quality and reducing the need for manual intervention.

In conclusion, robotic laser welding machines represent a significant leap forward in welding technology. Their ability to deliver unmatched precision and speed, coupled with their versatility and safety features, make them an indispensable tool for modern manufacturing. As we look to the future, it’s clear that these machines will play a pivotal role in shaping the next generation of industrial processes.