Rotational molding or rotomolding is a technique utilized to make hollow plastic-sort materials products. One of the vital ends of rotomolding is the option for textile. The material collection procedure is crucial to very last goods and services good quality, mainly because it has an impact on the sturdiness, toughness, effectiveness against deterioration, and overall …

Rotomolding

The Rotomolding Spectrum: A Comprehensive Overview of Plastic Innovation

The plastics market is one who has long been developing and altering. Technologies and procedures have made it possible to generate plastic materials that are much stronger, stronger, plus more adaptable than before. Just about the most revolutionary operations in the market is rotomolding. This process has revolutionized the way in which plastics are made, …

Progressive Applications of Rotomolding within the Plastic materials Sector

Rotational molding takes place when plastics are warmed and administered into an encased mildew to make the specified condition. Rotational molding has become popular recently as it delivers benefits, such as low-charge tooling, substantial production costs, excellent fine detail replication, and little or no scrap material. With this post, we will talk about reasons why …

Innovative Plastic Design: Mastering Rotational Molding

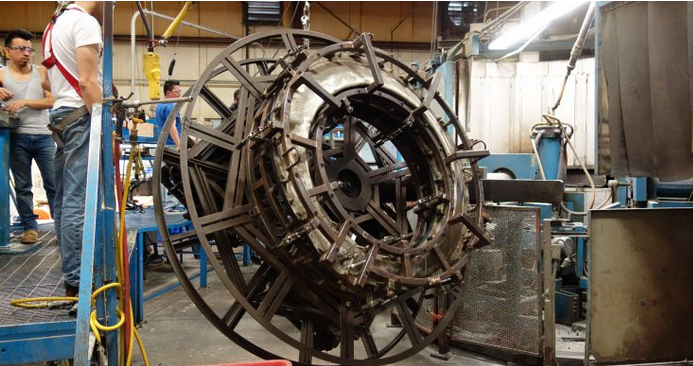

Rotomolding, also called rotational molding, is a manufacturing approach used for generating plastic merchandise. It requires heating a hollow mold, filled with plastic material resins, and rotating it around two axes to make the specified design. This manufacturing method made a great progress way since its creation from the 1940s, with numerous Rotational Molding improvements …

Rotomolding Innovations in the Plastics Industry

Rotational molding or Rotomolding is a well-liked developing approach for developing complex plastic material parts that happen to be too big to become manufactured by traditional injections molding. Among the crucial great things about Rotomolding is that it enables a wide array of materials to be utilized, each using their distinctive properties and advantages. In …

from the Stone Age to Rotational Molding: The Story of RotoMold Technology

Rotational molding can be a process that was invented inside the past due 1950s by Richard W. Boulanger, an professional for Common Electrical Plastics Company. On September 28, 1956, the very first patent was sent in and granted on October 17, 1960, as US Patent 2,912,991 – “Method of Washing Plastics Fabric.” It offers considering …

Sculpting Plastics: The Rotational Molding Way

In relation to designing plastic resources, there are a variety of methods offered. One of the more popular and adaptable methods is rotational molding. This impressive approach allows suppliers to produce sophisticated, hollow plastic-type material pieces of just about any form or dimensions. The process involves putting a hollow fungus in a big oven. The …

Rotomolding Applications: Where Precision Meets Performance

Rotomolding is actually a manufacturing process that has revolutionized the plastic-type material business. This is a exclusive and impressive method that shapes polymer goods into diverse designs and designs by spinning a fungus within an stove. It is a Rotomolding adaptable method that gives countless design and style opportunities and allows you to produce almost …

Unveiling the Rotomolding Process: How Plastic Products Are Born

Rotomolding, also called rotational molding, is actually a producing procedure that entails producing plastic-type merchandise with the use of high temperatures and rotational motion. This procedure is incredibly adaptable and may be used to produce a wide range of items, from large canisters to children’s Rotational Molding playthings. In this article, we’ll consider a closer …

Ways to get providers of Plastics Rotomoulding

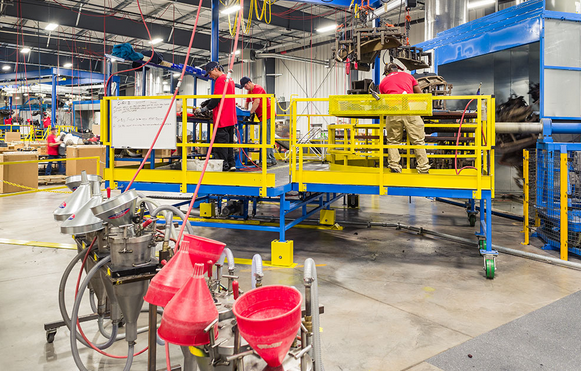

One of the wonderful advancements that were achieved in Rotomolding involves the lowering of charges due to the automation of functions such as the launching of Rotational Molding unprocessed materials, the closing and opening of molds, thus boosting quality as a result of efficient control over the temperature inside of the fungus, with the chance …