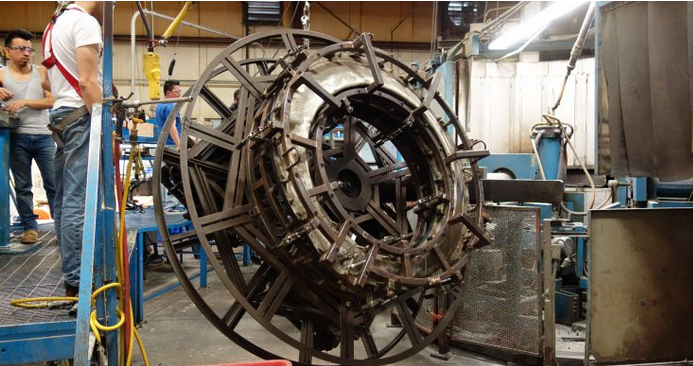

Rotomolding, also called rotational molding, is a manufacturing approach used for generating plastic merchandise. It requires heating a hollow mold, filled with plastic material resins, and rotating it around two axes to make the specified design. This manufacturing method made a great progress way since its creation from the 1940s, with numerous Rotational Molding improvements in technology and resources. Within this article, we are going to take a closer look at several of the most recent advancements in rotomolding techniques which may have transformed the plastic technology sector.

Multi-Layering Technology:

Multi-layering technological innovation is one of the most up-to-date developments in rotomolding. It requires layering several types of plastic-type materials to generate more powerful and much more tough items. Multiple-layering is particularly valuable in manufacturing tanks, receptacles, and boxes that need various layers to avoid rust or toxic contamination. The procedure involves incorporating a slender layer of plastic-type material coating for the outer top of the main product or service structure. It provides a top level of buffer security against hostile substances, Ultra-violet light, and environment variables.

three dimensional Generating:

3D publishing has been in existence for a while, nevertheless it merely has recently located its way into rotomolding. This technologies allows designers to produce highly complicated shapes and geometries that might have been extremely hard to attain with standard rotomolding. The procedure involves transforming laptop or computer-aided models (CAD) into actual things by layering polymers before the ideal form is obtained. three dimensional publishing has reduced the cycle times for prototyping and eradicated the necessity for high priced fungus tooling. It has enhanced accuracy and reliability and repeatability when reducing waste and materials fees.

Nano-Preservatives:

Nano-additives are little debris that happen to be included in plastic materials to enhance their functionality. They may be usually lower than 100 nanometers in proportion and are made of resources for example co2, silica, and aluminum oxides. Nano-chemicals enhance the physical properties of plastics, including toughness, durability, and adaptability. Additionally, they minimize permeability and increase resistance to heat and Ultra-violet light. In rotomolding, nano-artificial additives are widely used to improve the performance of storage units and tanks employed in industries like normal water treatment, compound storage, and pharmaceuticals.

Improvements in Resources:

New materials are constantly being created to enhance the overall performance of rotomolded goods. Biodegradable resources are one of the latest breakthroughs in rotomolding. They are made of normal natural resources like corn starchy foods, soybeans, and sugarcane, plus they degrade much faster than classic plastic materials. Naturally degradable plastics lessen environmental contamination and they are a sustainable substitute for petrol-dependent plastic materials. Other advancements in components include the growth of great-temperature plastic materials that may stand up to excessive conditions, and-overall performance plastic materials that can withstand abrasion, affect, and chemical assault.

simple:

Rotomolding can be a adaptable and cost-effective developing process that has sophisticated significantly in recent years. Innovative systems such as multiple-layering, 3 dimensional printing, nano-artificial additives, and new components have contributed to much stronger, more durable, and green items. These advancements have opened new techniques for development and artistic design in sectors including auto, health care, aerospace, and customer items. The way forward for rotomolding appearance bright, therefore we can anticipate seeing much more breakthroughs in plastic material technology in the coming years.